HP Neverstop Laser Printers are the world's first toner tank, rapid-reload printers designed to help customers and the environments. Previously, replacing toner meant disposing cartridges and introducing plastic and metal waste into the environment. Along with the innovative Toner Reload Kit, customers can now -

Refill the Neverstop Laser Printer toner tanks in less than 15 seconds.

My role

As Design Lead, I led interaction and industrial design execution for HP’s Neverstop Laser Printer (CTSS1), the world’s first cartridge free, rapid reload laser printer. I collaborated closely with external R&D partners and cross functional teams across Vancouver, Singapore, and South Korea to navigate technical and user experience challenges.

Through iterative user research and prototyping, I refined critical details from ergonomics to cost sensitive manufacturing decisions to deliver a clean, intuitive refill workflow. The result: under 15 second toner reloads and a 50% reduction in plastic waste. This contributed to over 5 million projected unit sales and garnered multiple industry accolades, including IDEA, IFA, Red Dot, and Good Design awards.

How might we create an affordable toner solution that’s easy to use, delivers consistent print quality, and reduces environmental waste?

In emerging markets like India and Vietnam, customers often rely on third party toner refill services to save costs. This process requires dismantling cartridges and injecting generic toner, which is messy, inconvenient, and can compromise print quality or damage the printer. It also leads to higher warranty costs for HP. At the same time, traditional cartridge replacement systems create significant plastic and metal waste. The challenge was to design a new toner replacement experience that is clean, affordable, and intuitive, encouraging the use of genuine toner, reducing environmental impact, and improving long term customer satisfaction and business outcomes.

Turning Vision into Reality

The project began with a clear vision: to deliver a sustainable, premium unboxing and setup experience that matched the product’s innovative spirit. Turning that vision into reality meant translating it into user experience through materials, finish, form factor, and interaction —

all while balancing cost, logistics, and sustainability goals.

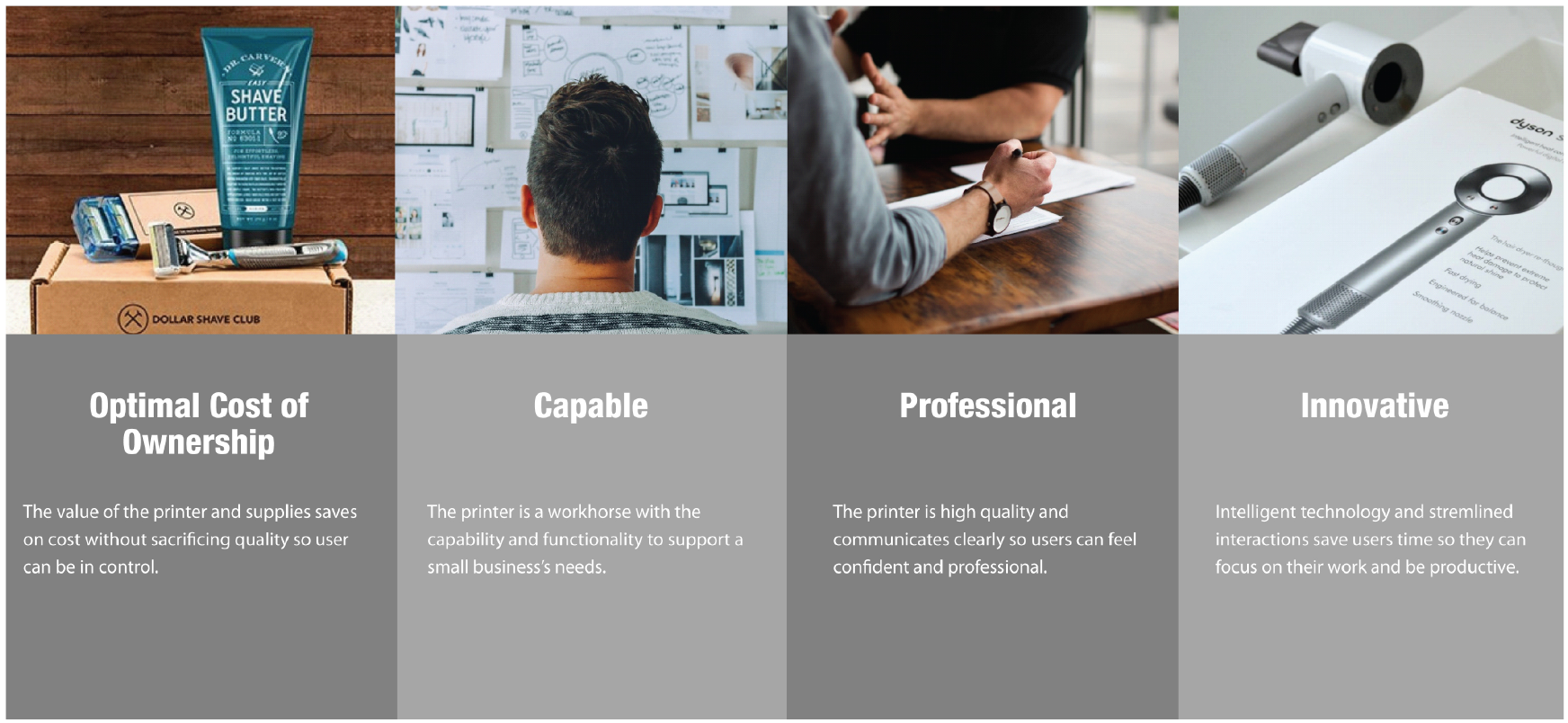

The CTSS (Continuous Toner Supply System) portfolio addressed several interconnected challenges -

creating a user-friendly visual language that was both intuitive and cohesive with its environment, reimagined the toner refill process to be effortless and mess-free to shift consumer perceptions and counter traditional refill practices in emerging markets, incorporating more recycled materials and reducing plastic usage to boost sustainability, and optimizing processes to lower the overall cost of ownership.

The goal was to create a holistic experience that captures the user journey from the out-of-the-box experience to printer setup, printing, and toner reloading.

Key objectives included:

Expressing the key HP Print VBL (Visual Brand Language)

Easy setup and intuitive use

50% less waste

15-second, mess-free toner reload

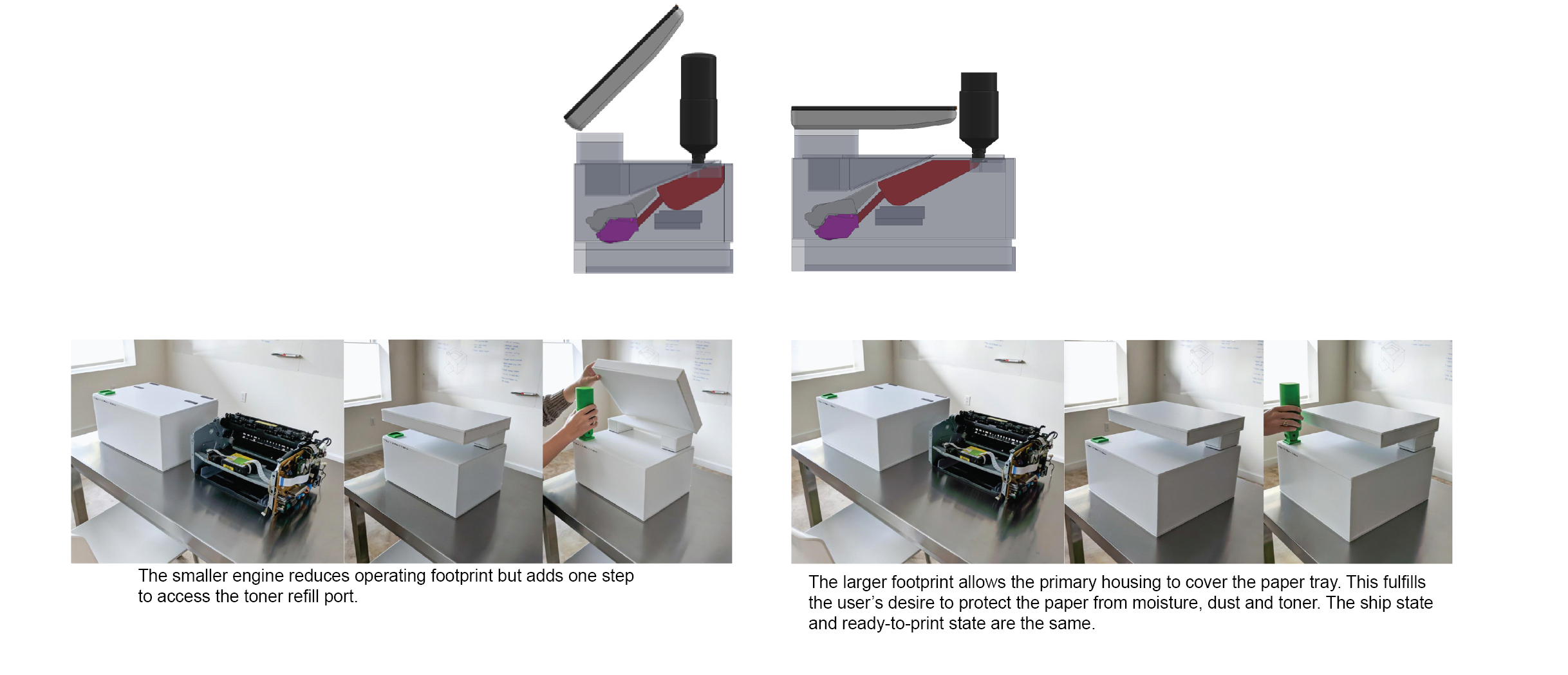

Architecture investigation & Trade-offs | Printer Engine

The architecture of the printer was critical, particularly in shaping the discovery and experience of the toner refill feature. It also had implications for palletization and shipping costs. To evaluate the trade-offs between user experience and logistics, cardboard prototypes were built to document and assess the experience. The final solution reduced the unit’s footprint, making it lighter and more space-efficient for countertops, while carefully testing the placement of the fill port to ensure intuitive user discovery.

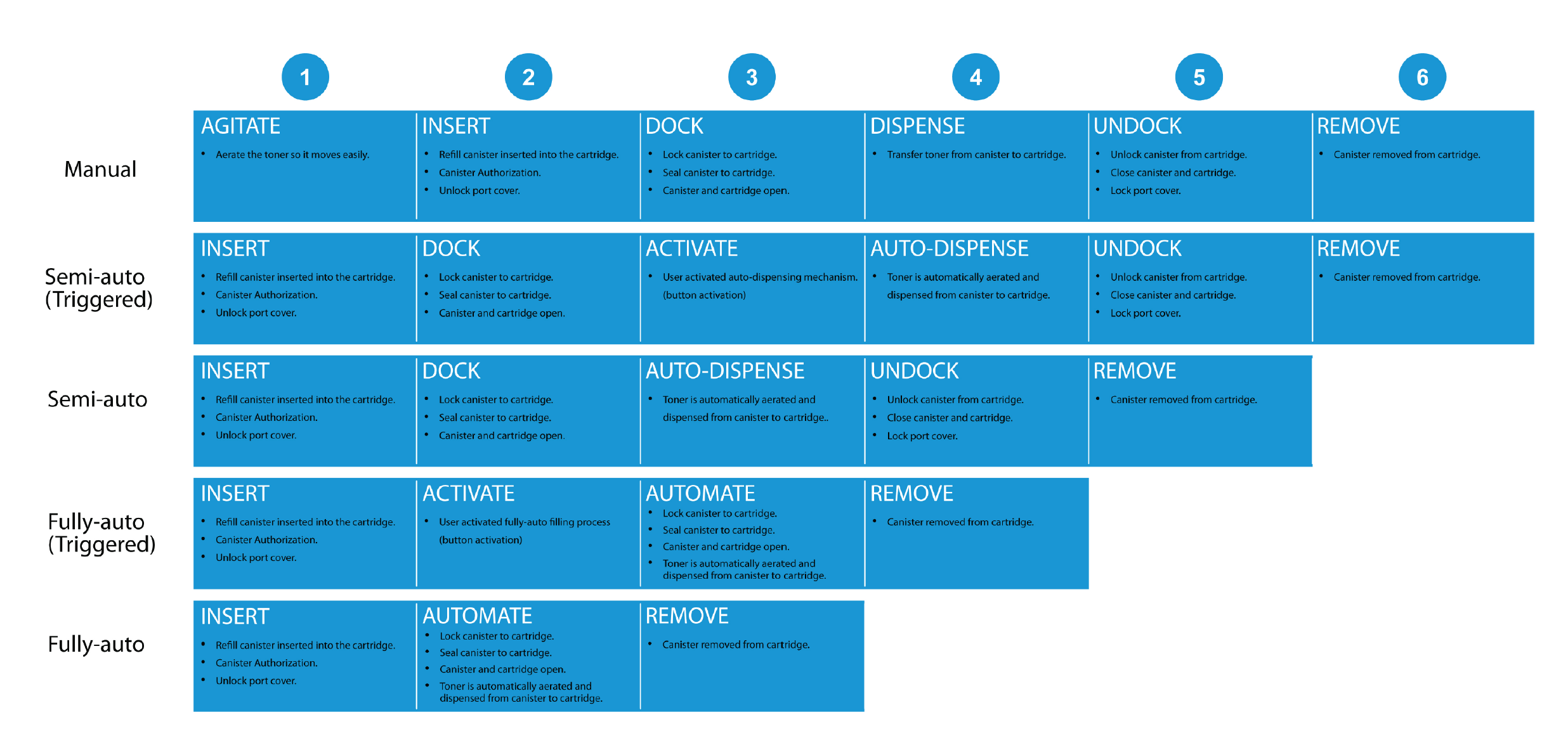

Architecture Investigation | Toner Reload Kit

Toner reloading methods explored in collaboration with an external consultancy to rapidly explore options and document user experience trade-offs.

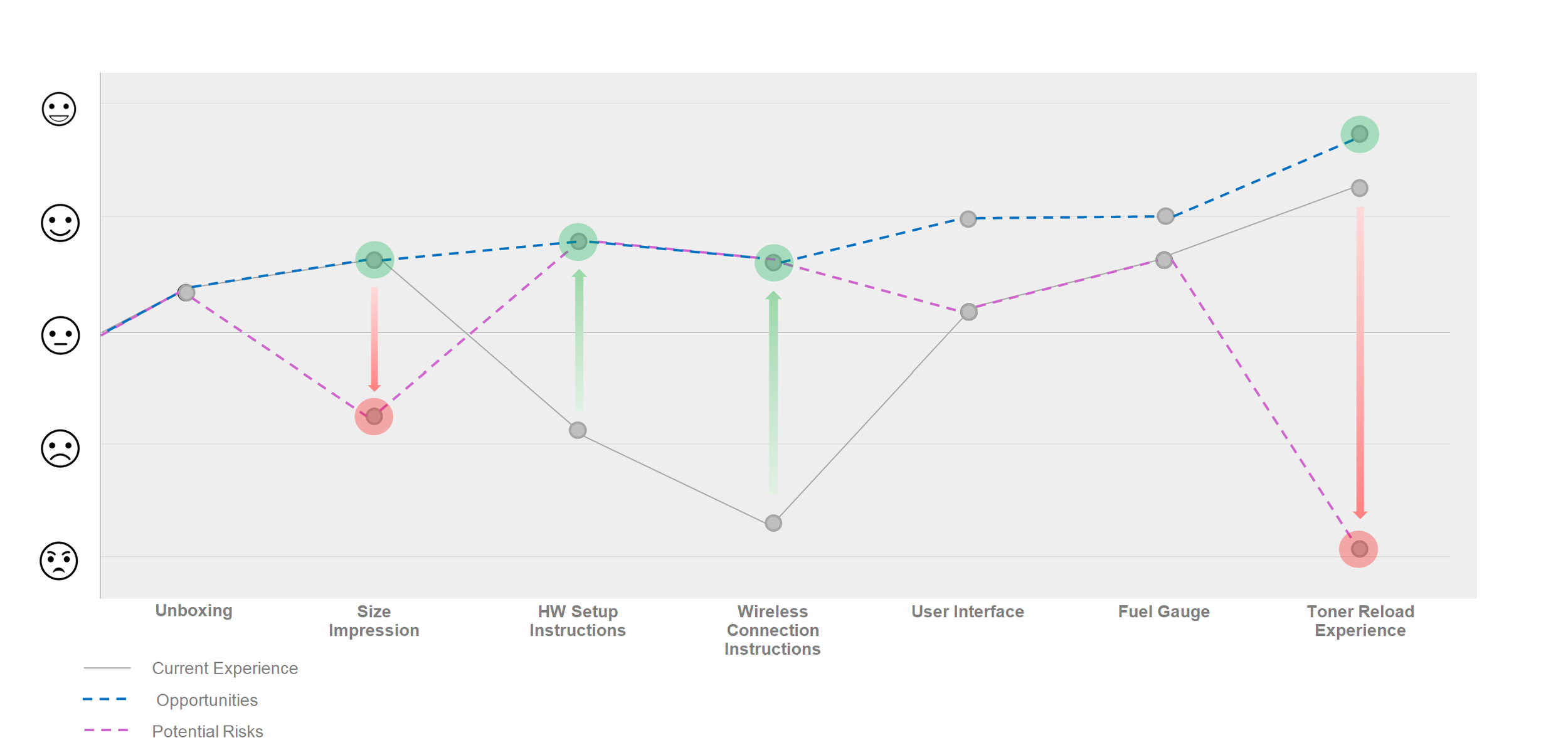

Qualitative Research | End-to-End Experience

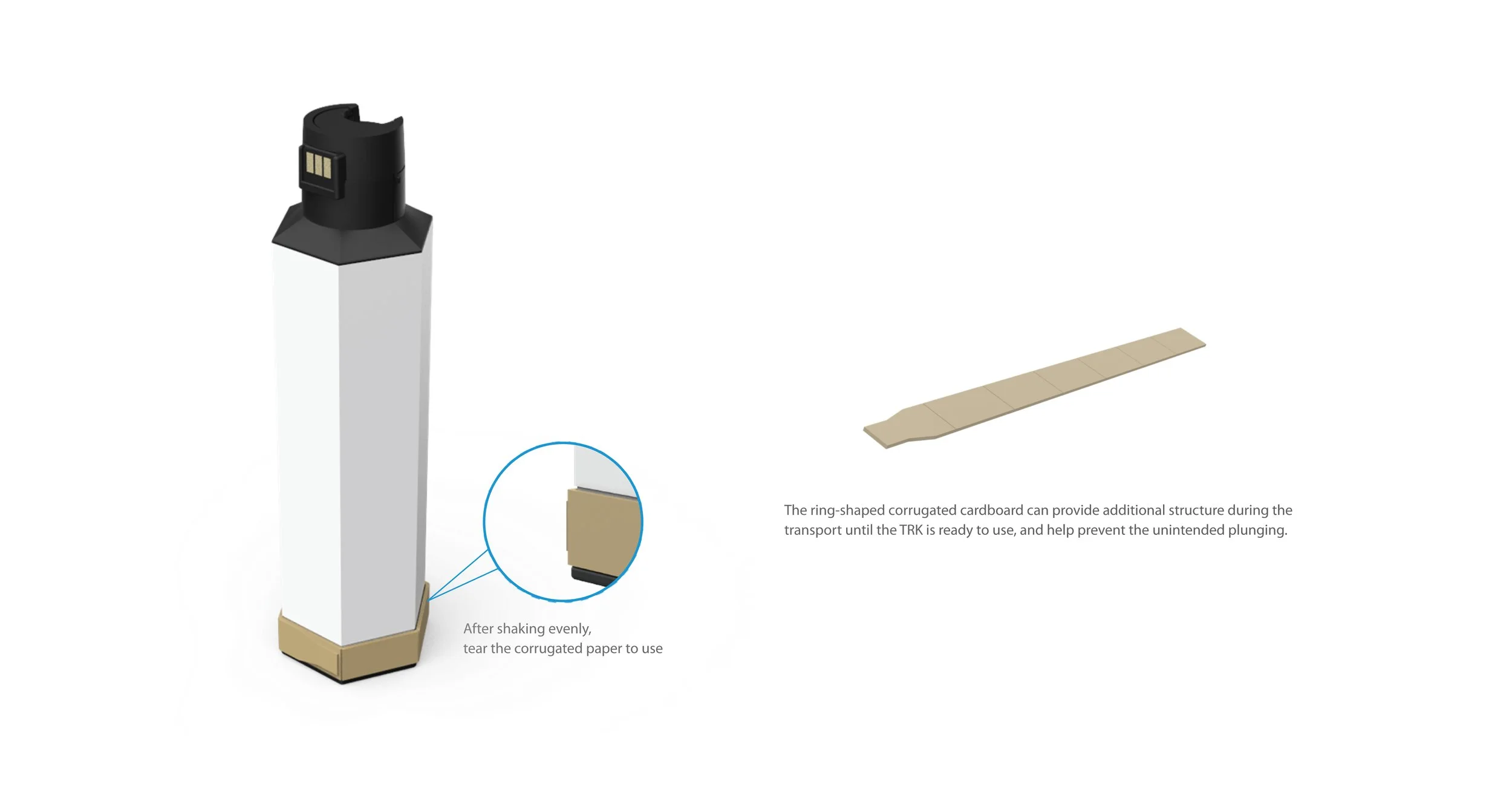

Qualitative research was conducted to gather insights into the current design intent and identify key focus areas for improving the user experience. For example, the success of the Toner Reload Experience heavily depended on ensuring that the toner was uncompacted prior to reload. Initial user testing also revealed that some users over-rotated the Toner Refill Kit (TRK) beyond 180 degrees, potentially damaging the imaging drum port. To address these issues, a clear instructional label was added to prompt users to shake the TRK, and a mechanical detent was integrated into the rotating locking collar to provide tactile feedback at the correct stop point. Both solutions were validated through user testing to ensure proper engagement and reinforce correct usage behavior.

Toner Reloading instruction on the TRK and Learnings material in the packaging

The Toner Reloading instructions on the TRK and the Learnings material included in the packaging, developed in collaboration with the OOBE team, were validated to prevent toner compaction.

User-Tested Design Fix: Preventing TRK Over-Rotation

During initial user testing, it was observed that some users rotated the Toner Refill Kit (TRK) beyond the intended 180 degrees after authentication, risking damage to the imaging drum port. To address this, I conceptualized and prototyped a tactile feedback mechanism through a minor modification to the existing locking collar, without adding any new parts or impacting cost targets. After sharing the research insights and tradeoffs, the solution was aligned with the cross functional team. Subsequent testing confirmed that the adjustment effectively prevented over rotation, improving both user experience and product safety.

Cost reduction | Packaging & Setup experience

Cost reduction became critical as the project focused on a profit-upfront model, rather than monetizing through supply sales as in the traditional printer sales model. This required multiple iterations to optimize the design, reducing logistics and parts costs while ensuring the original user experience intent was maintained.

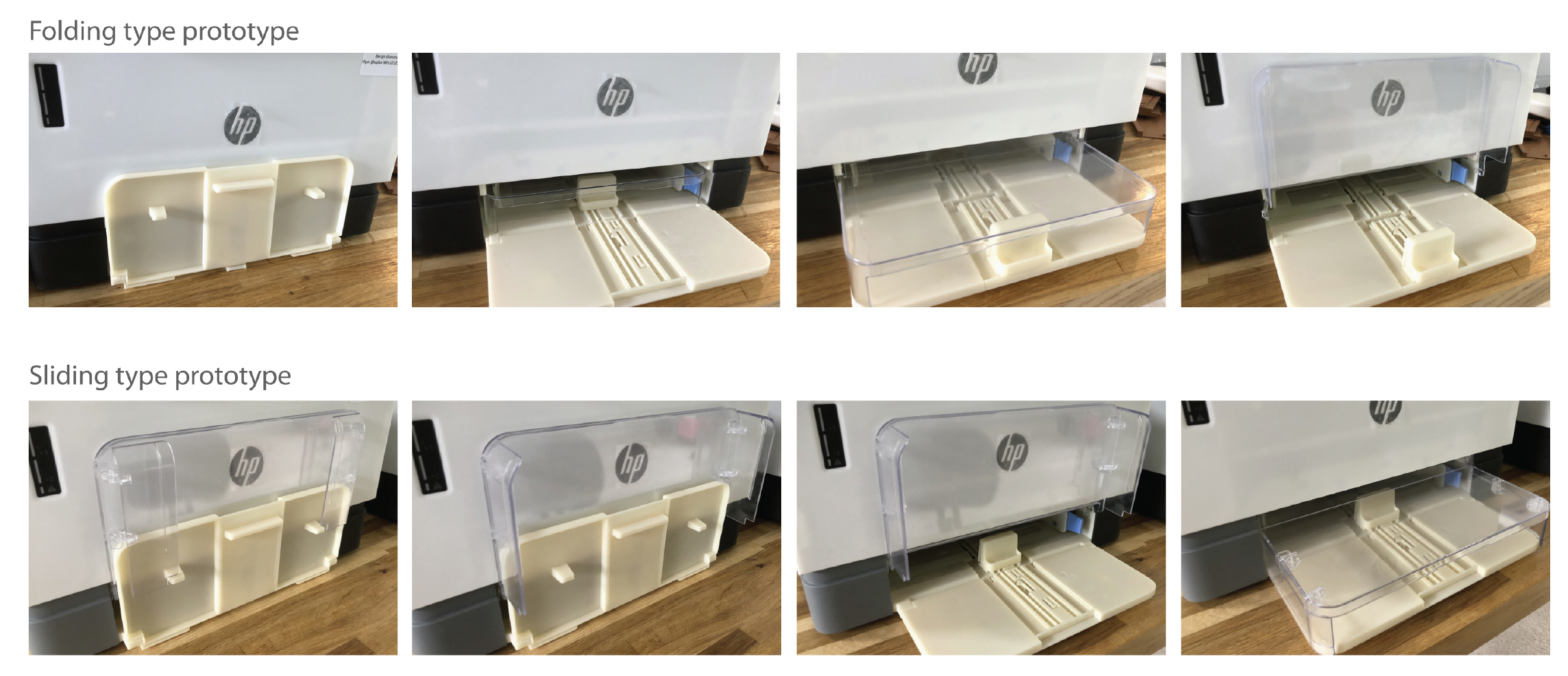

Paper Tray

The paper tray is an example of exploration that was done to streamline set-up experience while reducing the shipping foot print of the printer.

Toner Reload Kit

Toner reload kit concepts were explored to 1. Reduce packaging volume and 2. Utilize more sustainable materials.

Compact Toner Reload Kit

Concepts to reduce packaging volume were explored to improve shipping costs.

Eco-friendly, Fully recyclable Toner Reload Kit concept

Concepts for reducing plastic usage were explored to lower material consumption and reduce shipping costs.

Final Design Solution & Impact

5 million projected unit sales.

15-second, mess-free toner reload

Toner reload kits use up to 50% less material than traditional cartridges.

100+ patents filed

Recognized by major design awards: IDEA, IFA, Red Dot, and Good Design.